Oxidized Bitumen

Bitumen Products: Oxidized Bitumen for Industrial Applications

Oxidized Bitumen, also referred to as blown bitumen or hard bitumen, is produced by passing air through penetration-grade bitumen. This process modifies the bitumen’s properties, enhancing its durability, flexibility, and temperature resistance. Oxidized Bitumen is widely used in industrial applications such as roofing, waterproofing, and insulation due to its exceptional chemical stability and adhesion properties.

Extreme climate conditions make oxidized bitumen a preferred choice for construction and industrial purposes, offering long-lasting solutions for demanding environments.

Grades of Oxidized Bitumen

Oxidized bitumen comes in various grades, each tailored to specific industrial needs. The grades are typically classified based on their softening point and penetration values, which define the material’s flexibility and heat resistance.

Oxidized Bitumen 85/25

- Oxidized Bitumen 85/25 Oxidized Bitumen 85/25 is a versatile grade, known for its flexibility and moderate temperature resistance. It is commonly used in waterproofing applications, roof felt production, and as an adhesive for insulation panels. Its balanced performance makes it a go-to option for many construction projects.

Oxidized Bitumen 90/40

- With a higher softening point, Oxidized Bitumen 90/40 is ideal for applications requiring high heat resistance. This grade is used in the manufacturing of electrical products, rubber compounds, and industrial coatings. Its resistance to cracking under thermal stress makes it a popular choice for harsh environments.

Oxidized Bitumen 95/25

- This grade offers a balance between flexibility and durability. Oxidized Bitumen 95/25 is commonly used in industrial applications such as pipe coating, joint filling, and sealing membranes. It is highly resistant to weathering and oxidation, providing long-term stability in demanding conditions.

Oxidized Bitumen 105/35

- Oxidized Bitumen 105/35 is designed for high-temperature applications, making it suitable for use in industrial flooring, road construction, and protective coatings. Its high softening point ensures it remains stable under heat, offering enhanced protection for surfaces exposed to high temperatures.

Oxidized Bitumen 115/15

- This grade is primarily used in the production of roofing materials and bitumen-based paints. Oxidized Bitumen 115/15 offers superior adhesion, weatherproofing properties, and a long service life, making it ideal for construction projects exposed to harsh climate.

Bitumen Packing: Preserving Quality During Transport

To maintain the quality and performance of oxidized bitumen, proper packing methods are essential. Our company offers several packing options to suit your project requirements:

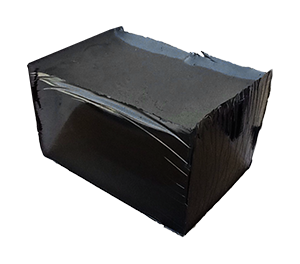

Block Packing

Bitumen can be formed into solid blocks and packed in high-density plastic or carton boxes, making it easier to handle and store at industrial sites.

Kraft Paper Bags

Oxidized bitumen can be packed in 25 kg or 50 kg kraft paper bags, ideal for easy handling and transport to project sites.

Polyethylene Bags

These bags offer additional protection against moisture, ensuring the bitumen remains intact during long-term storage or overseas transport.

Drums

Oxidized bitumen is often stored in 180-kg or 200-kg steel drums. This method is widely used for larger quantities, ensuring the bitumen is securely transported and remains uncontaminated.

Essential Details of Oxidized Bitumen Grades

| Grade | Application | Softening Point (°C) | Penetration (dmm) | Heat Resistance |

|---|---|---|---|---|

| Oxidized Bitumen 85/25 | Roofing, waterproofing | 85 | 25 | Moderate |

| Oxidized Bitumen 90/40 | Electrical products, coatings | 90 | 40 | High |

| Oxidized Bitumen 95/25 | Pipe coating, sealing | 95 | 25 | Very High |

| Oxidized Bitumen 105/35 | Industrial flooring, roadways | 105 | 35 | Extreme |

| Oxidized Bitumen 115/15 | Roofing materials, paints | 115 | 15 | Superior |

Specification Sheet of Oxidized Bitumen Grades

- These specifications ensure that project managers and engineers have the precise information they need to choose the correct grade of bitumen for their industrial or construction needs. Please contact us for detailed specification sheets for any grade.